Secondary Operations

Engineered to transform formed parts into finished assemblies.

Assembly

CNC Trimming

Machining & Drilling

Injection Foaming

Plastitel USA delivers integrated secondary operations that extend thermoforming into complete, production-ready solutions. Trimming, machining, assembly, and foam integration are engineered as part of the manufacturing flow to support dimensional accuracy, functional integration, and repeatable production performance.

Our teams align secondary operations with part geometry, material behavior, and end-use requirements to ensure each component advances efficiently from formed sheet to finished assembly.

Process Integration

Secondary operations structured around production intent.

Secondary operations are defined early to align forming, trimming, and assembly into a cohesive manufacturing strategy. Fixture design, tolerance management, part handling, and sequencing are engineered together to support consistent output, controlled interfaces, and scalable production.

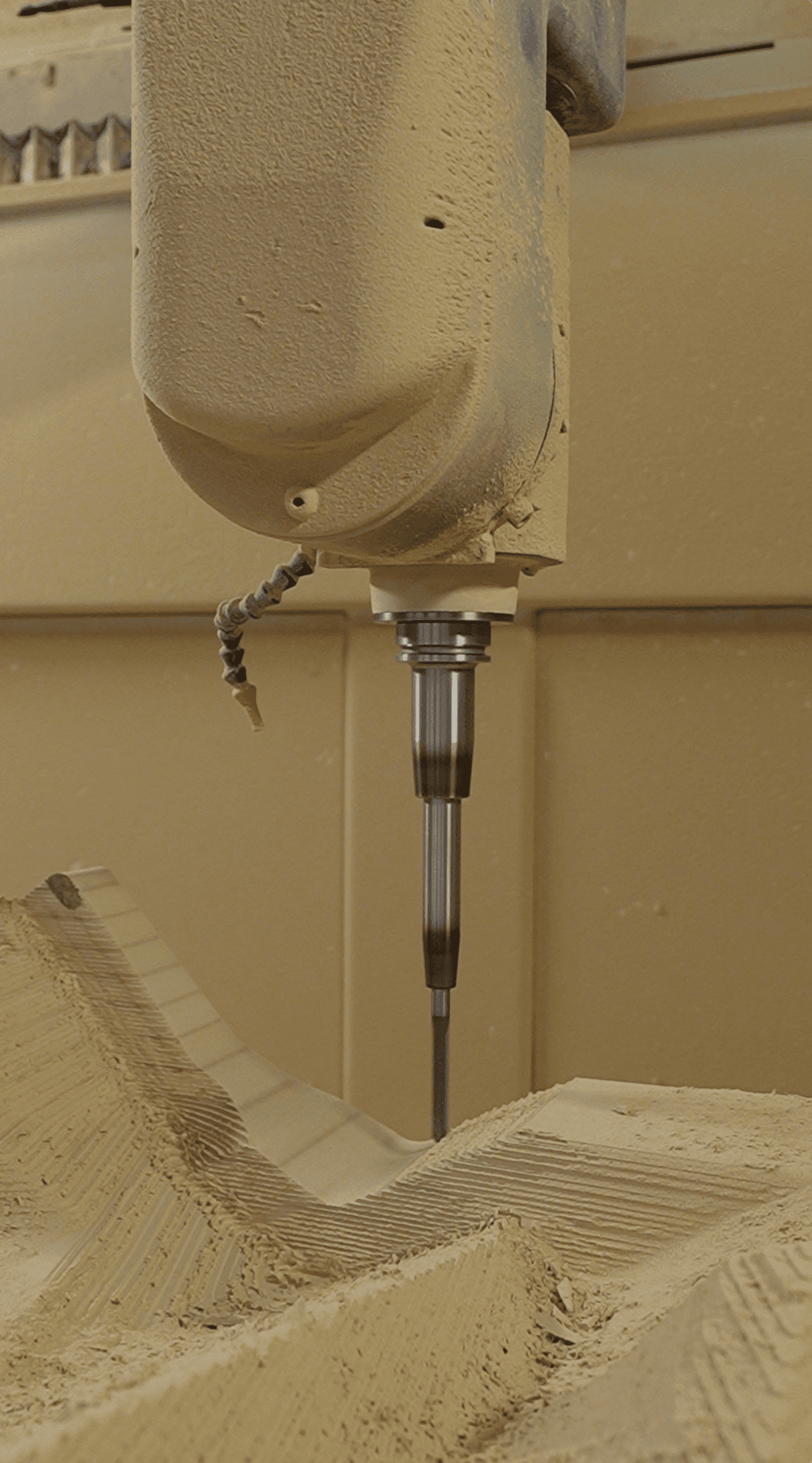

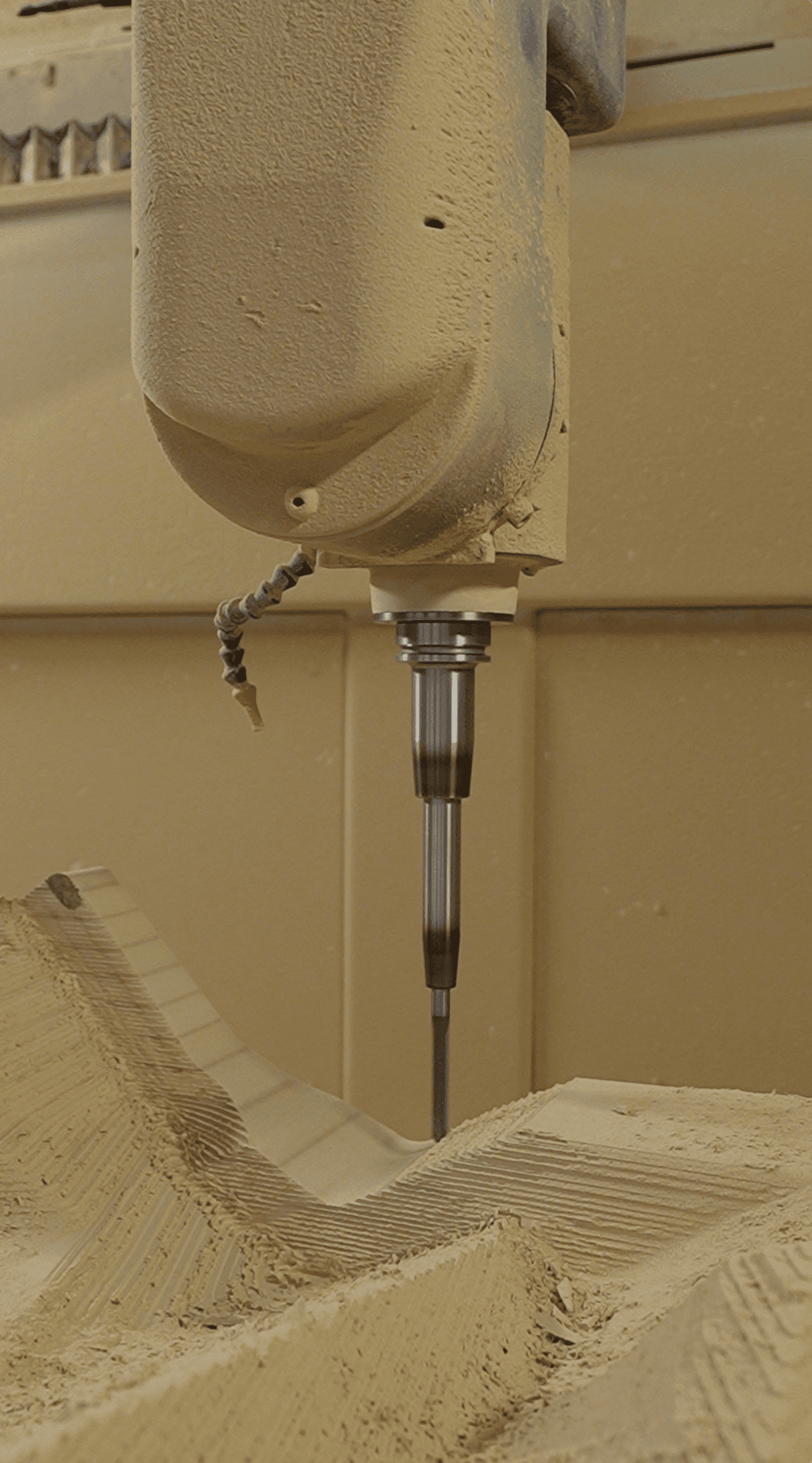

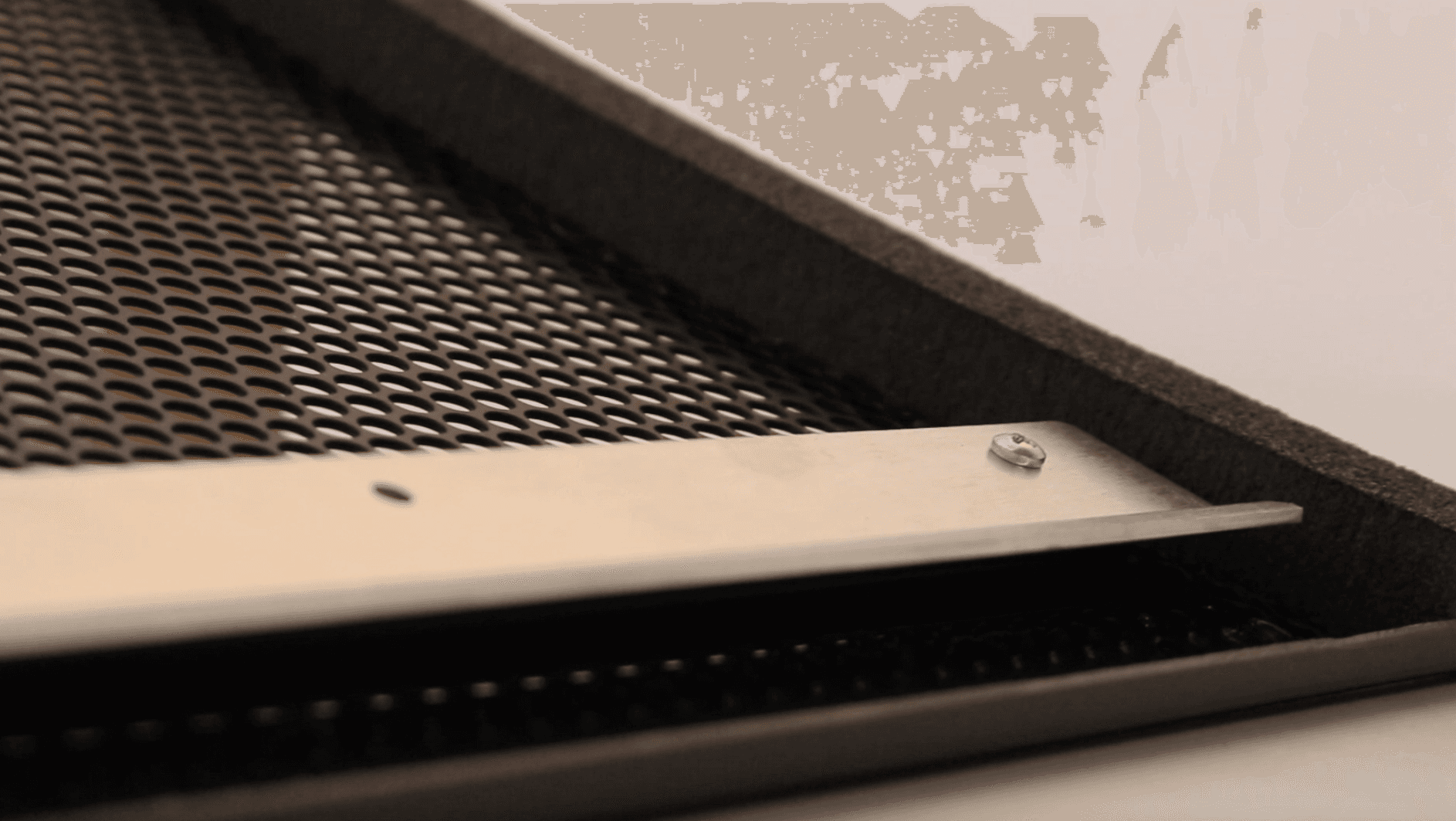

CNC Trimming

Precision trimming for dimensional accuracy and repeatability.

CNC trimming delivers controlled edge definition, consistent cut quality, and precise feature placement. Tool paths and fixturing are engineered to preserve part geometry, support tight tolerances, and maintain repeatable results across production volumes.

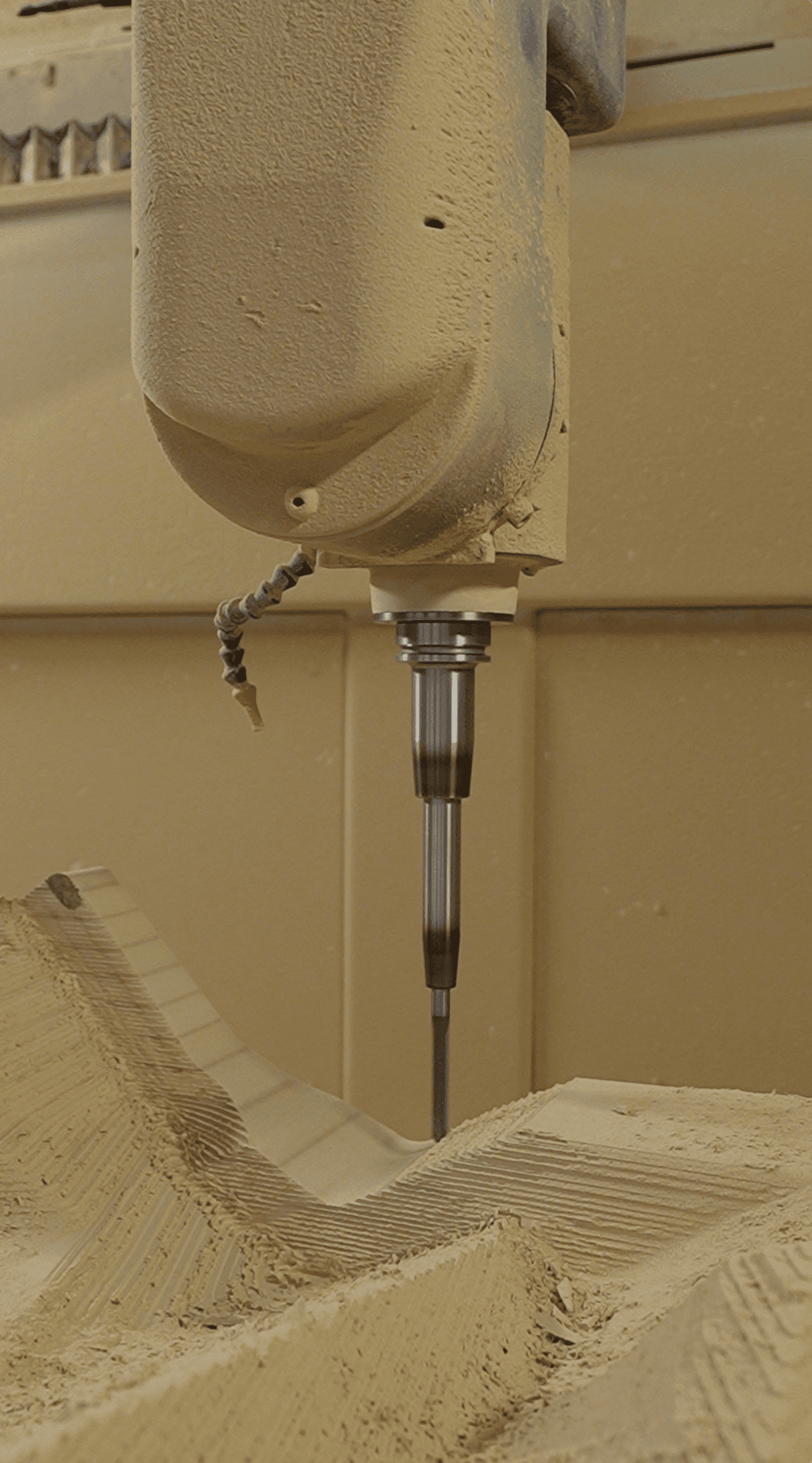

Machining & Drilling

Post-form machining engineered for functional integration.

Machining and drilling operations add functional features such as openings, inserts, mounting points, and interfaces. These operations are integrated into the production workflow to support accurate alignment, clean finishes, and reliable assembly performanc

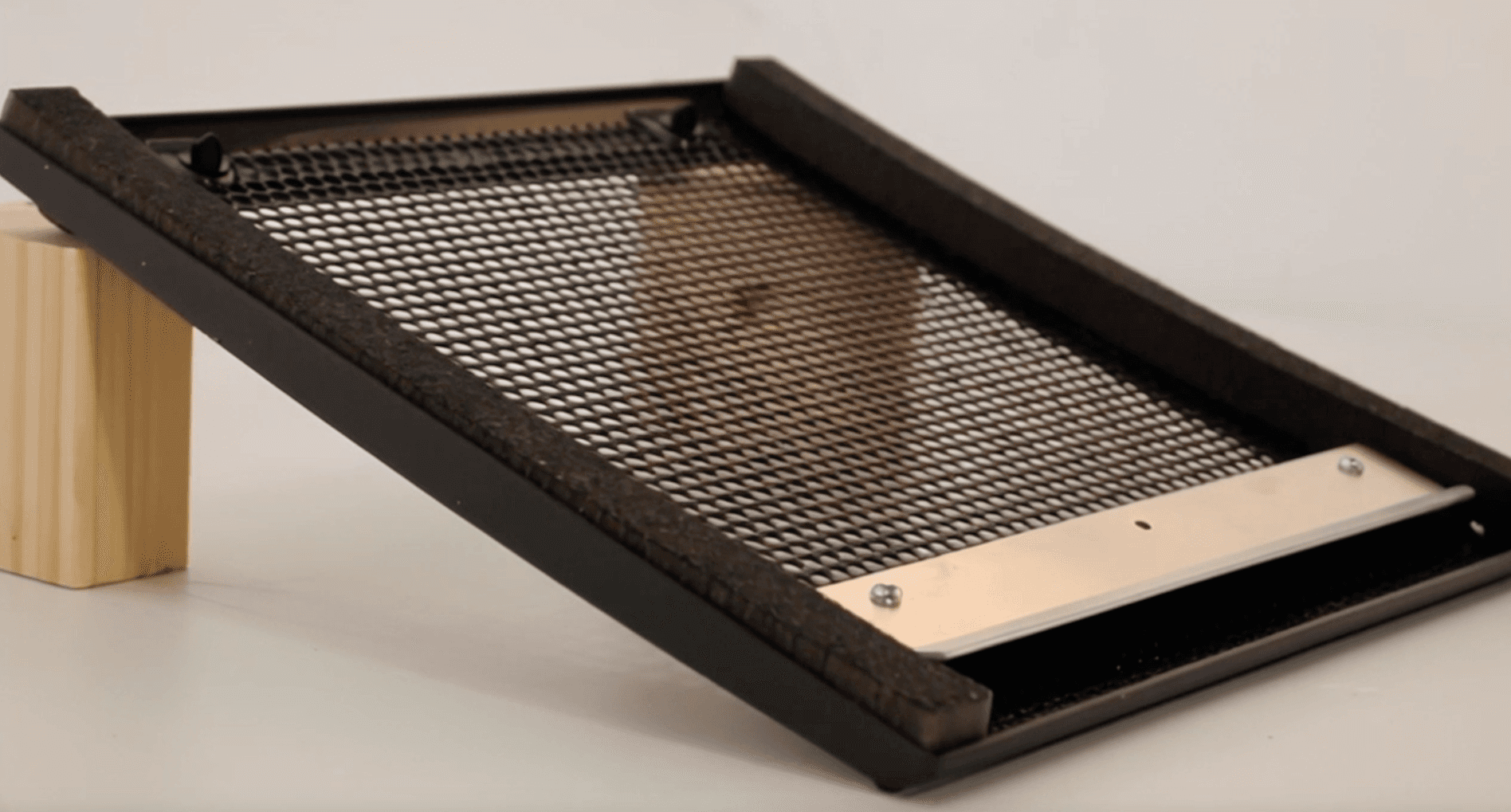

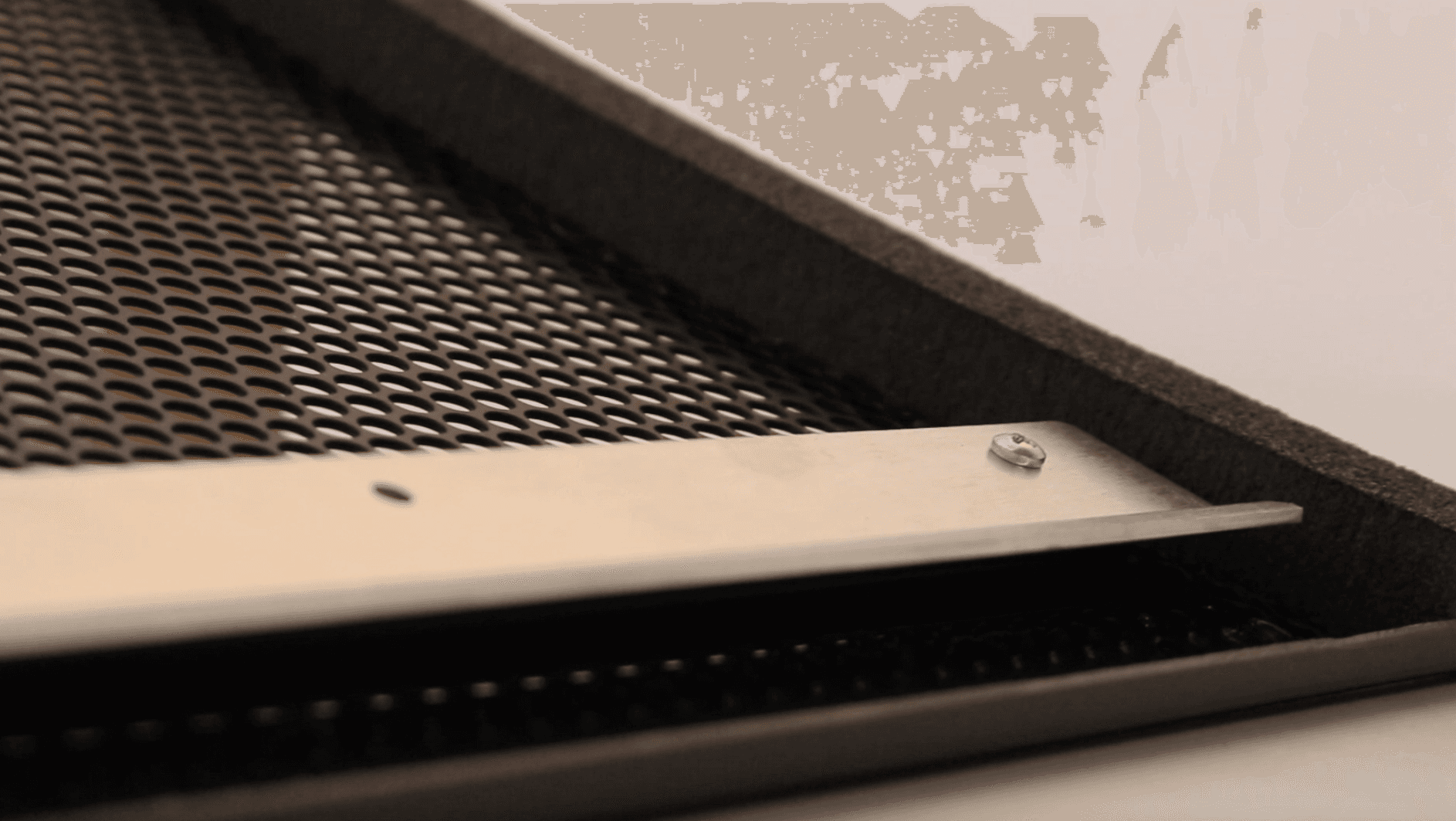

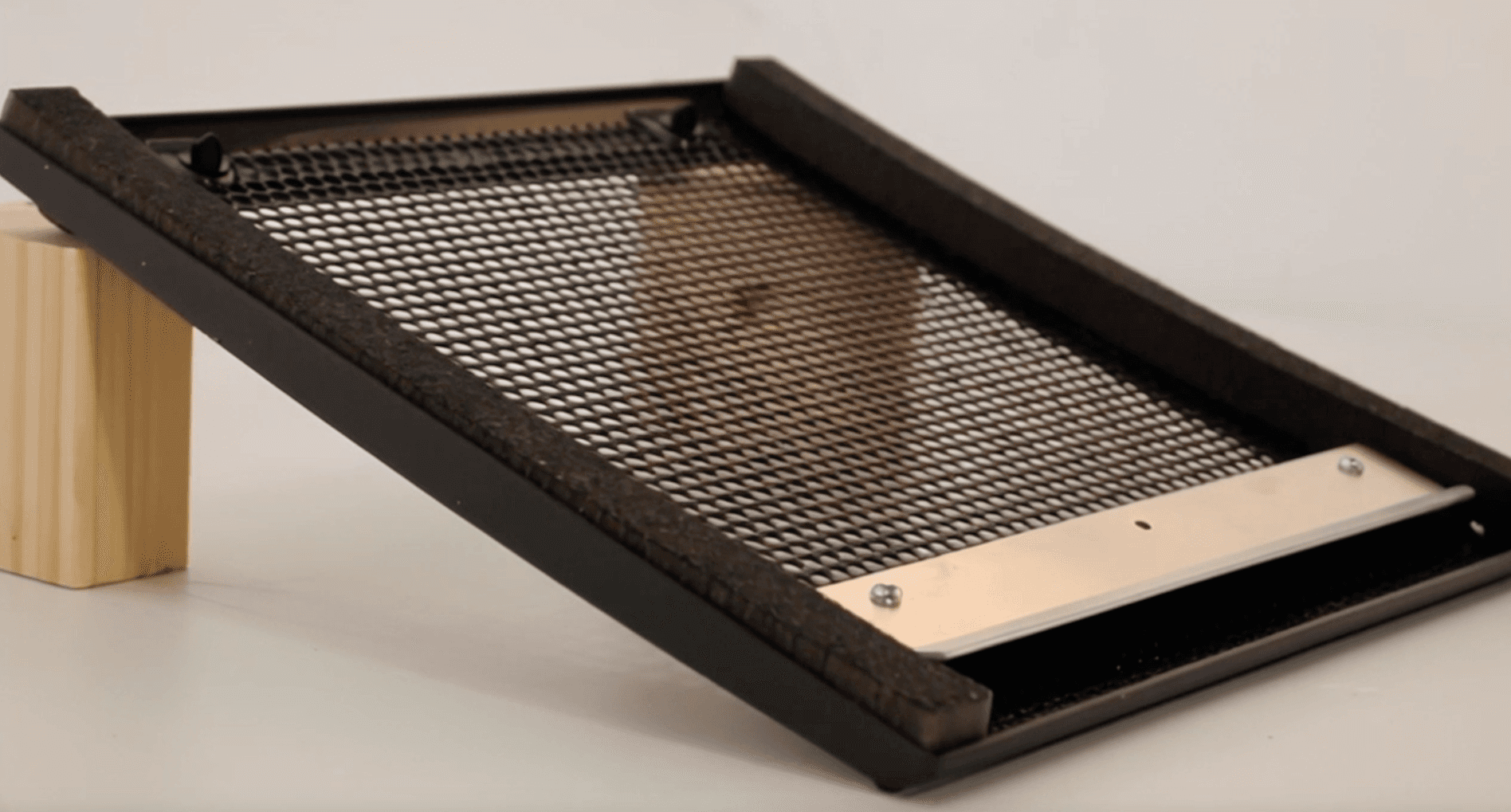

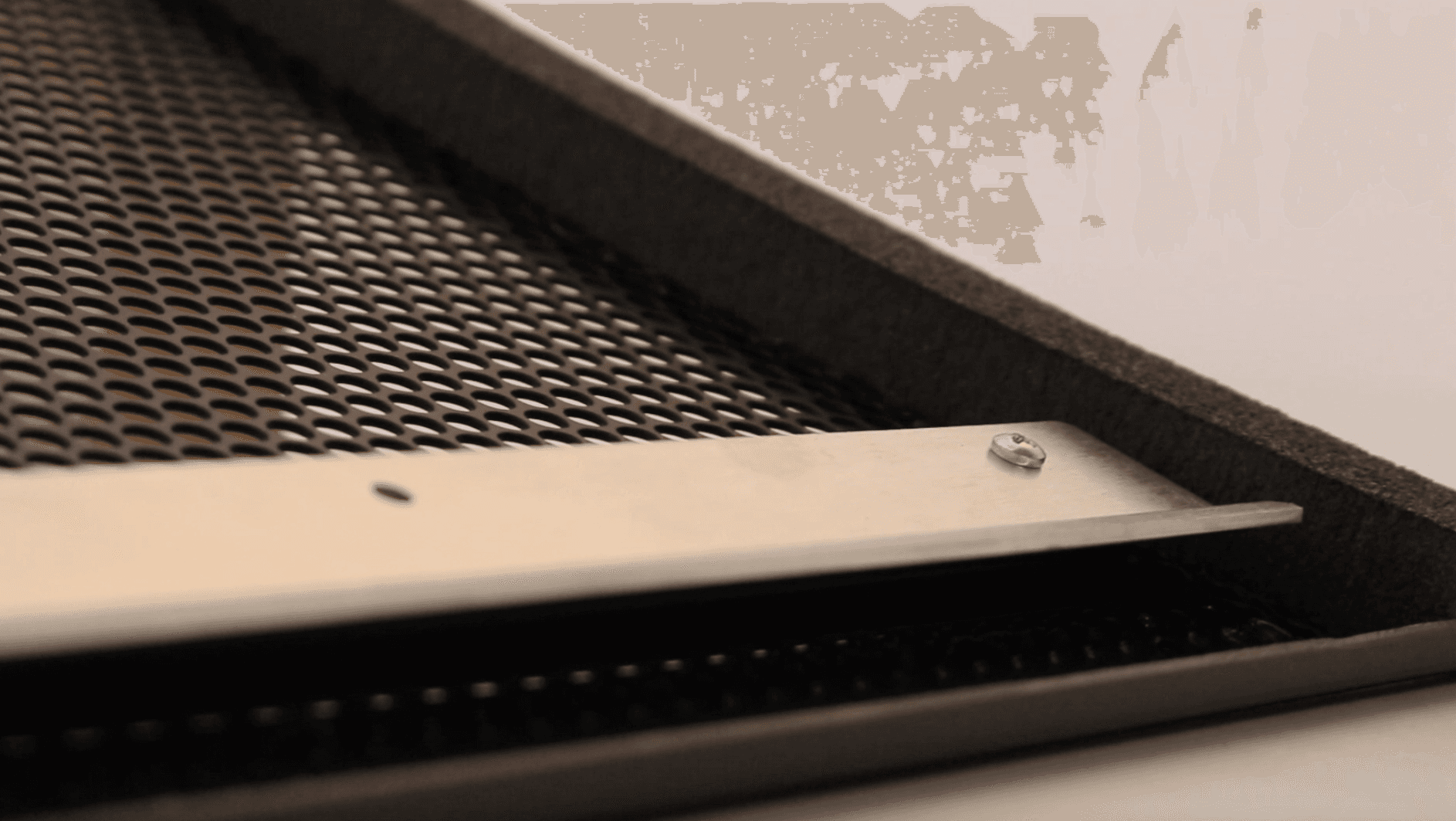

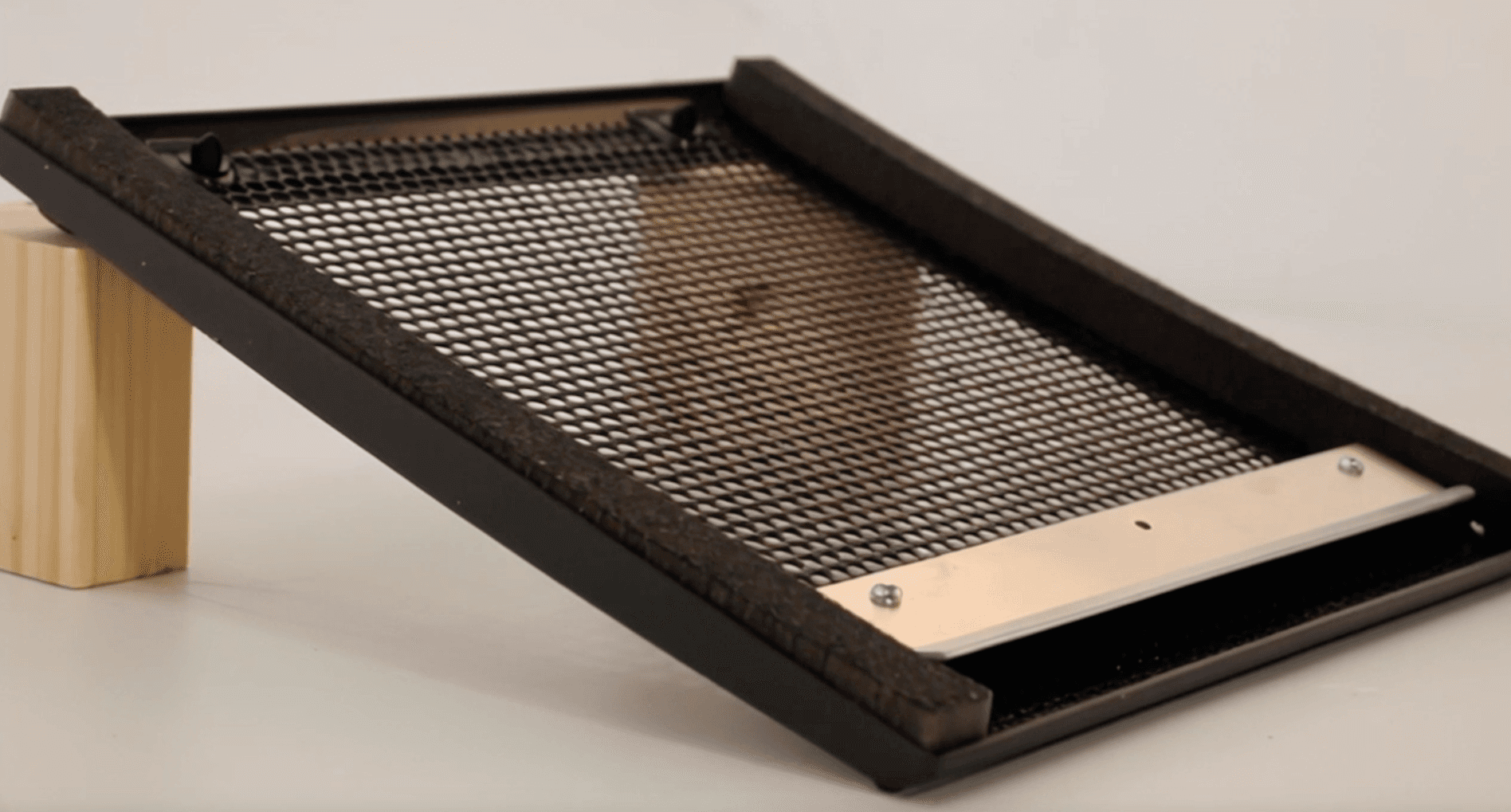

Assembly & Partial Assembly

Integrated assembly solutions tailored to program requirements.

Assembly and partial assembly operations combine thermoformed components with hardware, inserts, and complementary materials to create finished products or functional sub-assemblies. Processes are engineered to ensure consistent fit, structural integrity, and efficient downstream integration across production volumes.

Injection Foaming

Structural reinforcement and insulation integrated directly into the part.

Injection foaming enhances rigidity, thermal performance, and acoustic behavior by filling internal cavities with controlled foam expansion. This process supports structural stability, vibration control, and long-term durability across a wide range of applications.

Program Capability

A unified platform for forming, finishing, and assembly.

Secondary operations at Plastitel USA operate within an integrated manufacturing environment where trimming, machining, assembly, and foaming function as a single system. This structure supports efficient execution, consistent quality, and scalable production for complex multi-step programs.

More Services

Secondary Operations

Engineered to transform formed parts into finished assemblies.

Assembly

CNC Trimming

Machining & Drilling

Injection Foaming

Plastitel USA delivers integrated secondary operations that extend thermoforming into complete, production-ready solutions. Trimming, machining, assembly, and foam integration are engineered as part of the manufacturing flow to support dimensional accuracy, functional integration, and repeatable production performance.

Our teams align secondary operations with part geometry, material behavior, and end-use requirements to ensure each component advances efficiently from formed sheet to finished assembly.

Process Integration

Secondary operations structured around production intent.

Secondary operations are defined early to align forming, trimming, and assembly into a cohesive manufacturing strategy. Fixture design, tolerance management, part handling, and sequencing are engineered together to support consistent output, controlled interfaces, and scalable production.

CNC Trimming

Precision trimming for dimensional accuracy and repeatability.

CNC trimming delivers controlled edge definition, consistent cut quality, and precise feature placement. Tool paths and fixturing are engineered to preserve part geometry, support tight tolerances, and maintain repeatable results across production volumes.

Machining & Drilling

Post-form machining engineered for functional integration.

Machining and drilling operations add functional features such as openings, inserts, mounting points, and interfaces. These operations are integrated into the production workflow to support accurate alignment, clean finishes, and reliable assembly performanc

Assembly & Partial Assembly

Integrated assembly solutions tailored to program requirements.

Assembly and partial assembly operations combine thermoformed components with hardware, inserts, and complementary materials to create finished products or functional sub-assemblies. Processes are engineered to ensure consistent fit, structural integrity, and efficient downstream integration across production volumes.

Injection Foaming

Structural reinforcement and insulation integrated directly into the part.

Injection foaming enhances rigidity, thermal performance, and acoustic behavior by filling internal cavities with controlled foam expansion. This process supports structural stability, vibration control, and long-term durability across a wide range of applications.

Program Capability

A unified platform for forming, finishing, and assembly.

Secondary operations at Plastitel USA operate within an integrated manufacturing environment where trimming, machining, assembly, and foaming function as a single system. This structure supports efficient execution, consistent quality, and scalable production for complex multi-step programs.

More Services

Secondary Operations

Engineered to transform formed parts into finished assemblies.

Assembly

CNC Trimming

Machining & Drilling

Injection Foaming

Plastitel USA delivers integrated secondary operations that extend thermoforming into complete, production-ready solutions. Trimming, machining, assembly, and foam integration are engineered as part of the manufacturing flow to support dimensional accuracy, functional integration, and repeatable production performance.

Our teams align secondary operations with part geometry, material behavior, and end-use requirements to ensure each component advances efficiently from formed sheet to finished assembly.

Process Integration

Secondary operations structured around production intent.

Secondary operations are defined early to align forming, trimming, and assembly into a cohesive manufacturing strategy. Fixture design, tolerance management, part handling, and sequencing are engineered together to support consistent output, controlled interfaces, and scalable production.

CNC Trimming

Precision trimming for dimensional accuracy and repeatability.

CNC trimming delivers controlled edge definition, consistent cut quality, and precise feature placement. Tool paths and fixturing are engineered to preserve part geometry, support tight tolerances, and maintain repeatable results across production volumes.

Machining & Drilling

Post-form machining engineered for functional integration.

Machining and drilling operations add functional features such as openings, inserts, mounting points, and interfaces. These operations are integrated into the production workflow to support accurate alignment, clean finishes, and reliable assembly performanc

Assembly & Partial Assembly

Integrated assembly solutions tailored to program requirements.

Assembly and partial assembly operations combine thermoformed components with hardware, inserts, and complementary materials to create finished products or functional sub-assemblies. Processes are engineered to ensure consistent fit, structural integrity, and efficient downstream integration across production volumes.

Injection Foaming

Structural reinforcement and insulation integrated directly into the part.

Injection foaming enhances rigidity, thermal performance, and acoustic behavior by filling internal cavities with controlled foam expansion. This process supports structural stability, vibration control, and long-term durability across a wide range of applications.

Program Capability

A unified platform for forming, finishing, and assembly.

Secondary operations at Plastitel USA operate within an integrated manufacturing environment where trimming, machining, assembly, and foaming function as a single system. This structure supports efficient execution, consistent quality, and scalable production for complex multi-step programs.

More Services