Quality & validation

Quality systems and validation processes built for production confidence.

PPAP

Inspection & Testing

Process Validation

Metrology

Plastitel USA delivers robust quality and validation frameworks that support consistent production performance, controlled processes, and dependable product conformity. Quality planning, validation, and inspection are embedded directly into manufacturing programs to align engineering intent with real production conditions.

Our quality systems support early validation, disciplined execution, and ongoing performance monitoring across all stages of the product lifecycle.

Quality Planning

Structured quality frameworks aligned with production requirements.

Quality planning begins at the program definition stage. Control plans, inspection strategies, validation requirements, and documentation are aligned with part geometry, material selection, and customer specifications to support predictable production outcomes and repeatable quality performance.

PPAP

Production Part Approval Process built for production readiness.

PPAP supports formal validation of production processes and part conformity prior to full-scale manufacturing. Documentation, dimensional results, material data, and process evidence are compiled to demonstrate readiness, process capability, and alignment with customer and industry standards.

First Article Inspection (FAI)

Initial part validation for dimensional and functional conformity.

First Article Inspection verifies that initial production parts meet defined specifications and engineering intent. Dimensional layouts, feature verification, and documented results provide a clear baseline for ongoing production and quality control.

Process Validation

Validated processes engineered for repeatable performance.

Process validation confirms that manufacturing parameters consistently deliver parts that meet defined requirements. Forming conditions, trimming operations, assembly steps, and secondary processes are evaluated and documented to support stable output, controlled variation, and long-term production reliability.

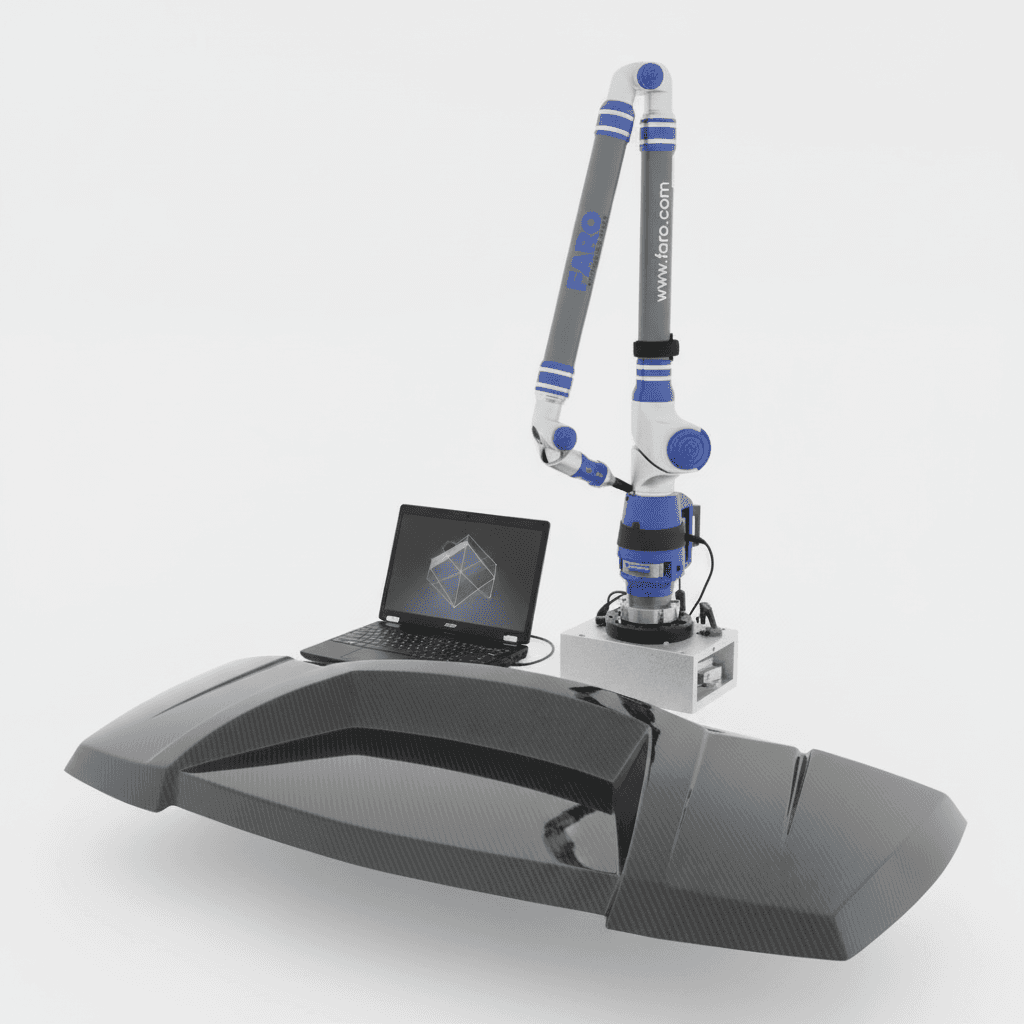

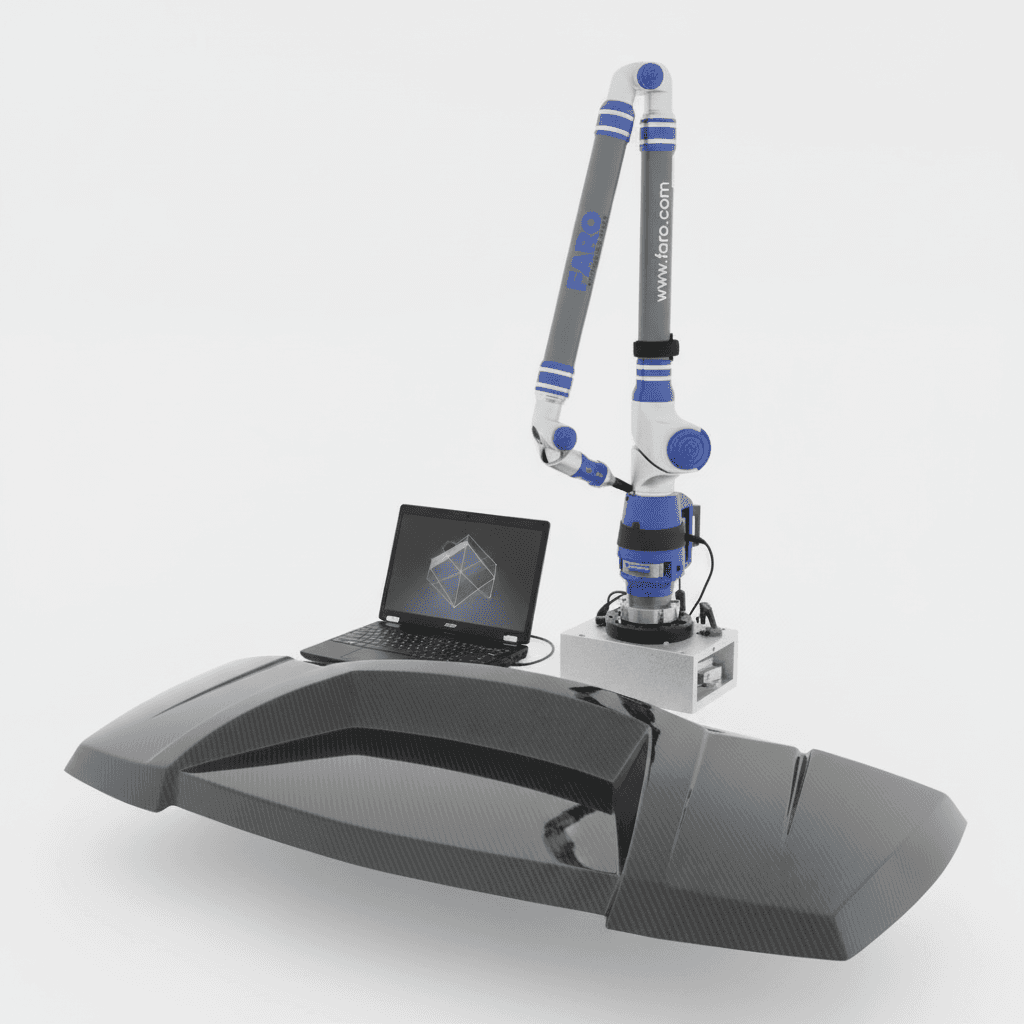

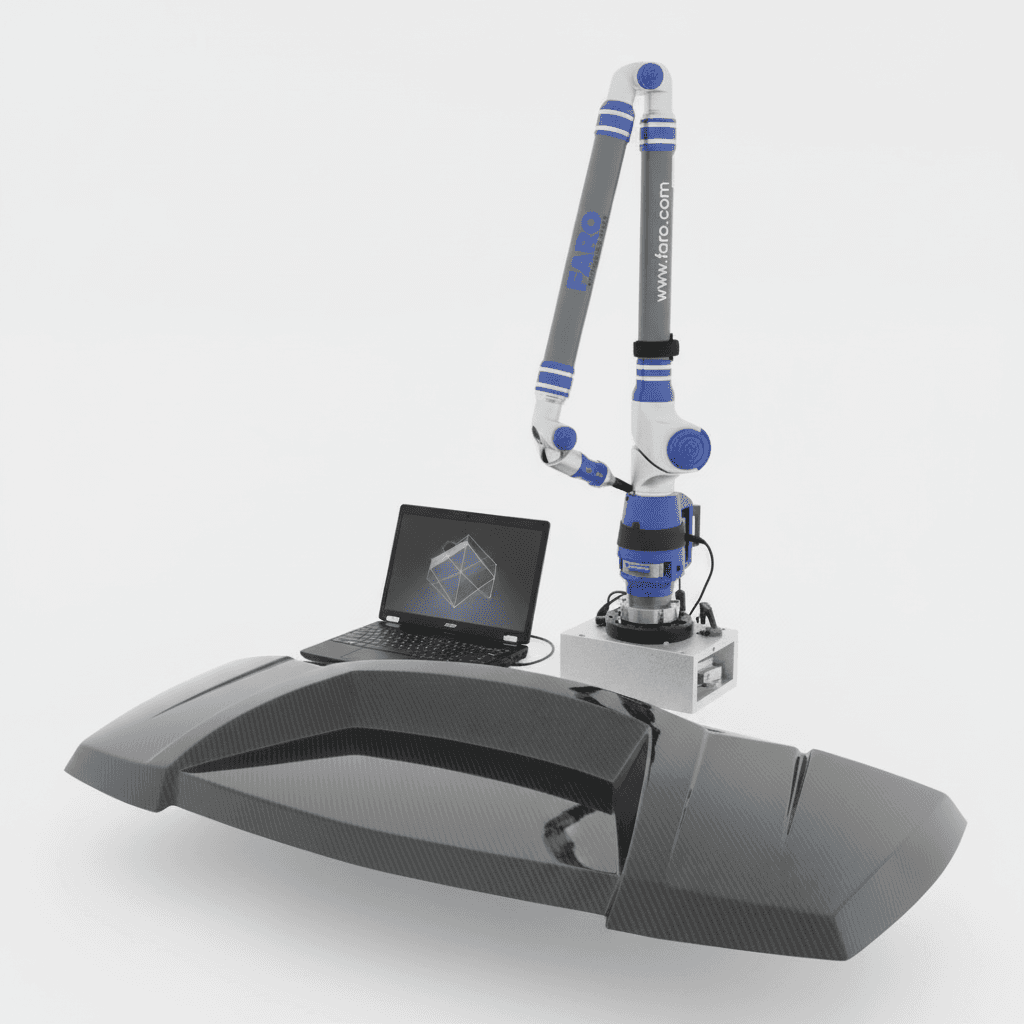

Metrology

Precision measurement supporting dimensional control.

Metrology capabilities support accurate measurement of complex thermoformed geometry. Advanced measurement tools and inspection methods verify critical dimensions, interfaces, and tolerances, supporting process control and continuous production alignment.

Inspection & Testing

Ongoing verification for consistent production quality.

Inspection and testing activities monitor product conformity throughout production. Visual inspection, dimensional verification, and functional testing support consistent quality performance and provide documented assurance across production volumes.

More Services

Quality & validation

Quality systems and validation processes built for production confidence.

PPAP

Inspection & Testing

Process Validation

Metrology

Plastitel USA delivers robust quality and validation frameworks that support consistent production performance, controlled processes, and dependable product conformity. Quality planning, validation, and inspection are embedded directly into manufacturing programs to align engineering intent with real production conditions.

Our quality systems support early validation, disciplined execution, and ongoing performance monitoring across all stages of the product lifecycle.

Quality Planning

Structured quality frameworks aligned with production requirements.

Quality planning begins at the program definition stage. Control plans, inspection strategies, validation requirements, and documentation are aligned with part geometry, material selection, and customer specifications to support predictable production outcomes and repeatable quality performance.

PPAP

Production Part Approval Process built for production readiness.

PPAP supports formal validation of production processes and part conformity prior to full-scale manufacturing. Documentation, dimensional results, material data, and process evidence are compiled to demonstrate readiness, process capability, and alignment with customer and industry standards.

First Article Inspection (FAI)

Initial part validation for dimensional and functional conformity.

First Article Inspection verifies that initial production parts meet defined specifications and engineering intent. Dimensional layouts, feature verification, and documented results provide a clear baseline for ongoing production and quality control.

Process Validation

Validated processes engineered for repeatable performance.

Process validation confirms that manufacturing parameters consistently deliver parts that meet defined requirements. Forming conditions, trimming operations, assembly steps, and secondary processes are evaluated and documented to support stable output, controlled variation, and long-term production reliability.

Metrology

Precision measurement supporting dimensional control.

Metrology capabilities support accurate measurement of complex thermoformed geometry. Advanced measurement tools and inspection methods verify critical dimensions, interfaces, and tolerances, supporting process control and continuous production alignment.

Inspection & Testing

Ongoing verification for consistent production quality.

Inspection and testing activities monitor product conformity throughout production. Visual inspection, dimensional verification, and functional testing support consistent quality performance and provide documented assurance across production volumes.

More Services

Quality & validation

Quality systems and validation processes built for production confidence.

PPAP

Inspection & Testing

Process Validation

Metrology

Plastitel USA delivers robust quality and validation frameworks that support consistent production performance, controlled processes, and dependable product conformity. Quality planning, validation, and inspection are embedded directly into manufacturing programs to align engineering intent with real production conditions.

Our quality systems support early validation, disciplined execution, and ongoing performance monitoring across all stages of the product lifecycle.

Quality Planning

Structured quality frameworks aligned with production requirements.

Quality planning begins at the program definition stage. Control plans, inspection strategies, validation requirements, and documentation are aligned with part geometry, material selection, and customer specifications to support predictable production outcomes and repeatable quality performance.

PPAP

Production Part Approval Process built for production readiness.

PPAP supports formal validation of production processes and part conformity prior to full-scale manufacturing. Documentation, dimensional results, material data, and process evidence are compiled to demonstrate readiness, process capability, and alignment with customer and industry standards.

First Article Inspection (FAI)

Initial part validation for dimensional and functional conformity.

First Article Inspection verifies that initial production parts meet defined specifications and engineering intent. Dimensional layouts, feature verification, and documented results provide a clear baseline for ongoing production and quality control.

Process Validation

Validated processes engineered for repeatable performance.

Process validation confirms that manufacturing parameters consistently deliver parts that meet defined requirements. Forming conditions, trimming operations, assembly steps, and secondary processes are evaluated and documented to support stable output, controlled variation, and long-term production reliability.

Metrology

Precision measurement supporting dimensional control.

Metrology capabilities support accurate measurement of complex thermoformed geometry. Advanced measurement tools and inspection methods verify critical dimensions, interfaces, and tolerances, supporting process control and continuous production alignment.

Inspection & Testing

Ongoing verification for consistent production quality.

Inspection and testing activities monitor product conformity throughout production. Visual inspection, dimensional verification, and functional testing support consistent quality performance and provide documented assurance across production volumes.

More Services